2014

Surface to In-Seam Mining Techniques

New autonomous directional mining generation of machines, tools, methods and processes by mechatronic autonomous systems (robots). Environmental Impact Studies [EIS] and Project Justifications vs Rehabilitations.

https://cadsolid-engineering.com

![(2) CadSolid-Engineering-Logo Bold [R200-G200-B200 HALF]](http://wordpress.cadsolid-engineering.com/wp-content/uploads/2014/04/2-CadSolid-Engineering-Logo-Bold-R200-G200-B200-HALF-300x111.png)

Typical Highwall Profile for recovery of outcropped seam mining material without removing mountain tops. Could be an extended mining operation before leaving open pit mining, trench mining or a contour mining operations. Recovery rates are high and about 70% on new seams and about 50% more by rectangle cutting of previous pre-augered round holes seams.

[Click on the Image to enlarge]

New Generation of Directional Slant Mining and/or Drilling Machines contributes to the Surface to In-Seam Techniques.

[Click on the Image to enlarge]

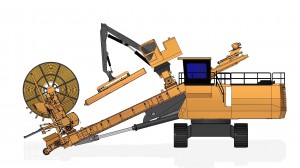

Current state of the art Highwall Horizontal Mining Machines contributes to the Surface to In-Seam Techniques.

Surface mining of coal completely eliminates existing vegetation, destroys the genetic soil profile, displaces or destroys wildlife and habitat, degrades air quality, alters current land uses, and to some extent permanently changes the general topography of the area mined.

For some extend facts your absolutely right, therefor Surface to In-Seam Techniques are developed, a open pit or mountain-top removal is not required to penetrate for surface to the pay-zones of minerals or degassing/dewatering insitu.

This justify the projects and rehabilitate the surroundings to absolute minimum, landscape soon after closing the entries makes sure the vegetation recover within a month time.

The wildlife area is very small a typical entry stroke takes less then a normal access road, air quality stay normal due to the fact there is no open pit or large land area use and therefor no permanently changes to any topography area mined.

Thanks you for this comment to give me the opportunity to explain why SIS-Techniques is a better mining way without moving mountains, rock-blasts, overburden replacing draglines and most of all safe-wise NO MINEWORKER GOES UNDERGROUND.